Optimizing Plant Engineering Services: The Key Steps in the Plant Layout Design Process | Steel Detailing India

Steel Detailing India offers a comprehensive range of integrated plant engineering services, including process, piping, mechanical, civil, procurement, and electrical engineering. Our team of experts is skilled in delivering top-notch solutions that are tailored to meet the unique needs of your project. With our expertise and attention to detail, you can trust us to provide reliable and efficient services for all your engineering requirements.

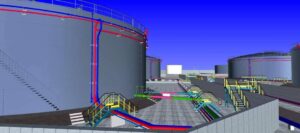

At Steel Detailing India, our Plant Design Engineering Services go above and beyond. We offer a wide range of services, including impeccable plant layout design, precise pipe stress analysis, and comprehensive structural analysis for the process industry. Our team specializes in optimized pipe routing to ensure maximum efficiency. With their extensive experience in the field, our experts are skilled in creating detailed piping isometric drawings and P&ID drafting. They are also proficient in providing top-notch General Arrangement Drawings and GA drawing services using industry-leading software such as AutoCAD Plant3D, Solidworks, and Autodesk Inventor. When it comes to plant design engineering, trust Steel Detailing India to deliver exceptional quality and expertise that exceeds expectations.

Process Engineering Services

At Steel Detailing India, we understand the diverse process requirements of our clients. Whether you’re dealing with batch or continuous processes, debottlenecking, pilot plant design and scale-up, or energy-related projects, we have the expertise to meet your needs. Our team is equipped with years of experience and extensive knowledge to provide comprehensive support for your project.

You can rely on our dedicated team to provide top-notch technical support, ensuring that the integrity of your plants remains uncompromised. Our experts are well-equipped to handle any technical challenges that may arise, giving you peace of mind knowing that your operations will run smoothly and efficiently.

Services

- PFD and P&ID redline markup update

- Process engineering support of all project lifecycle phases

- Process control narrative development

- Preparation of Process Documents (Equipment & Line List)

- Process Hazard Analysis (PHA)

- Hazard and Operability Study (HAZOP)

- Management of Change (MOC)

Piping Detail Engineering and Design Services

At Steel Detailing India, our GA drawing services and Piping Team go beyond traditional engineering. We are dedicated to being a valuable partner for our clients by optimizing plant layouts, equipment arrangements, and piping systems. Rest assured, we always prioritize client specifications, codes, and industry standards to deliver top-notch results.

The application of codes and standards, such as ANSI, API, and ASME, is essential in various industries. These codes and standards ensure compliance, safety, and uniformity in processes and practices.

Services

- Plot Plan, Equipment Layout and Skid Design

- Specifications based 3D Piping Modeling, Design, Orthographic Plan, Section, and Detail Preparation

- Pipe Stress & Flexibility Analysis

- Standard and Sustom Pipe Support Design

- Piping System Walkdowns

- GA Drawings & Isometric Extraction

- Material Take Off for Piping, Valves and Insulation

- Piping System Revamp Engineering

- Piping System Integrity Audit

Mechanical Design Engineering Services

Our exceptional Mechanical Design team at Steel Detailing India offers a wide range of valuable services to meet your engineering needs. From thorough Engineering Analysis to precise Detail Engineering, we are dedicated to providing top-notch support. We also specialize in efficient Data sheet preparation and reliable CAD Support, ensuring that every aspect of your project is handled with the utmost professionalism and attention to detail. Trust us to deliver excellence in all of our services.

Strengths

- The application of codes and standards such as ASME, IBR, TEMA, and API is essential in various industries. These codes and standards ensure the safety, reliability, and quality of products and processes. They provide guidelines and requirements that need to be followed to meet industry standards and regulations. By adhering to these codes and standards, companies can ensure compliance and maintain the highest level of quality in their operations.

- The core team possesses both design and fabrication experience.

Services

- Mechanical Design and Analysis for Pressure Vessels

- Thermal and mechanical design for shell and tube heat exchangers.

- The design and detailing of boilers, storage tanks, and silos.

- Preparation of GA (General Arrangement) and fabrication drawings.

Civil & Structural Engineering Services

At Steel Detailing India, our solutions are carefully crafted to prioritize safety and seamless integration with plant requirements. We understand the importance of cost-effectiveness as well. Our dedicated team meticulously analyzes the structural stability of systems, sizes the members accordingly, and designs connections to ensure optimal performance. Rest assured, our engineering solutions are thoroughly validated and reliable.

Strengths

Structural analysis and design utilize codes and standards such as AISC, IBC, IS, and NBC.

Services

- Structural Design & Analysis, Fabrication Drawings

- Equipment Support, Walkway, Ladder and Platform Design

- Foundation Drawings

- Connection Design

- Lifting arrangement design

- Cast-in-place concrete structures

- Monorail / Hoist systems

- Civil & Structural Material Take Off

- 3D Modeling & Steel Detailing

Electrical, Instrumentation & Control System Engineering Services

Steel Detailing India is your go-to solution for all your electrical, instrumentation, and control system engineering needs. Whether you’re setting up a new plant or refurbishing an existing one, we have you covered. Our team specializes in creating customized electrical engineering packages that align with your project requirements while taking into account your preferences on equipment origin and make. Trust us to deliver top-notch services that will exceed your expectations.

Strengths

- Having an in-depth understanding of codes such as IEC, NEMA, and NEC is crucial.

- Team with field experience

Services

- Junction Box design

- PLC Programming

- Heat tracing Layout and Electrical Circuit details preparation.

- Creation of:

- Instrument Hook-up Diagrams

- Single Line Diagrams (SLD)

- Instruments List & Logic Diagrams

- Cable Schedule and Wiring connection list

- Electrical circuit drawing

- Installation drawing

- Electrical GA Drawings, Wiring Diagrams and Wiring Lists

- Hazardous Area Classification Drawings

- Control System Architecture

- Instrument Specifications and Data Sheets

- Insulation procedure

- Bill of Materials

- Branch Circuit layouts & Panel arrangement

- 3D Modeling of Cable Trays and Instrument Panels

Procurement Engineering Services

Steel Detailing India assists customers in procuring engineered commodities and package units for process plants from the global market.

Strengths

- A robust database of relevant suppliers from around the world.

- Strong negotiations skills

- Strong engineering background

Pre-order Engineering Services

- We can assist you in finalizing the vendor list.

- Preparing the Technical Procurement Package.

- Technical Bid Analysis (TBA)

- Preparation of Purchase Specifications

Post-order Engineering Services

- Review of Vendor Drawings and Documents

- Expedition from Procurement to Shipment as per Production Schedule

- Finalization of ITPs

- Coordination with Inspection team, vendor & logistics team

- Final Documentation Support (Manufacturer Record book, Inspection Test report)

At Steel Detailing India, we offer a comprehensive range of integrated plant engineering services. Our expertise covers a wide array of disciplines, including process, piping, mechanical, civil, procurement, and electrical engineering. By providing all these services under one roof, we ensure seamless coordination and optimal efficiency for your projects. Trust us to deliver top-notch engineering solutions tailored to your specific needs.

9 thoughts on “Plant Engineering Services | Plant Layout Design Process | Steel Detailing”