The Role of Technology in Modern Structural Steel Detailing Processes

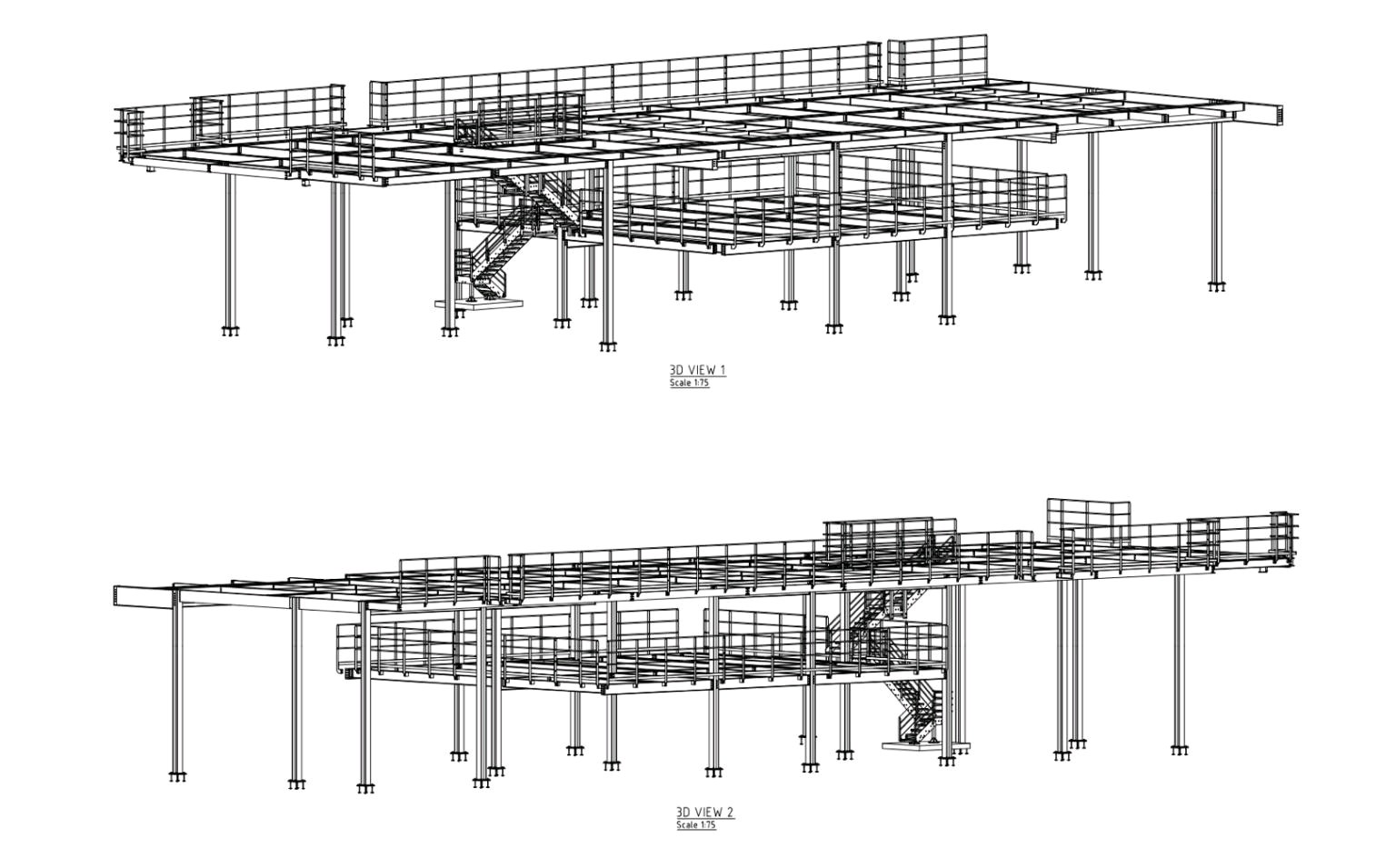

Steel Detailing Process – When it comes to describing a steel structure, we can think of it as a collection of various structural elements such as columns, plates, beams, floor plates, side wall covering members, roof members, and more. These elements come in different shapes and sizes and are securely connected to one another through welding or bolting. This not only ensures the structural integrity but also contributes to the durability of the overall construction.

The design engineer begins the process with a detailed design drawing that outlines crucial details such as the dimensions of steel members, their orientation, and precise location in 3D space. Additionally, they specify how these members should be interconnected. The engineer also includes important information about the aisle or overall bay dimensions of the building, floor levels, and even paint specifications. Furthermore, they carefully select the exact material from a range of available options to ensure optimal results.

Once the design drawing is finalized, it serves as a comprehensive tool for the contractor/fabricator/erector to assess various aspects of the project. This includes determining the overall scope of work, calculating precise quantities of materials required for each member size, estimating the time and resources needed to complete the job, identifying potential problem areas and gauging the level of complexity involved in execution. Armed with this valuable information, they are able to provide an accurate and fair price quote for carrying out the project.

- Gathering Project Information and Requirements – project information collection, client requirements gathering, project specifications

- Creating Accurate Structural Drawings and Models – steel drawings creation, 2D CAD modeling, BIM modeling, structural analysis software

- Determining Optimal Connections and Joints – welded connections design, bolted connections design, joint details optimization

- Generating Material Lists and Bill of Quantities (BOQ) – BOM generation for steel fabrication, material takeoff for estimating purposes

- Incorporating Design Changes and Coordination with Other Disciplines – design modifications management, coordination with architects & MEP engineers

- Reviewing Drawings for Accuracy and Quality Assurance – drawing review process, quality control in steel detailing

- Delivering Final Detailed Drawings to Fabricators & Contractors – drawing submission to fabricators or contractors, shop drawings preparation

After securing the project, it’s time for the contractor to take action and start executing it. While the initial design drawing served its purpose, it is no longer sufficient for carrying out specific tasks such as precise material cutting, determining length and shape requirements, and drilling bolt holes in the proper locations for seamless connection with other project components. To ensure accuracy and efficiency during construction, more detailed instructions are needed. To ensure a smooth construction process, the contractor must have precise plans and drawings for each structural element. This includes specifying all the essential details such as shape, size, cutting length, diameter, and precise location of connecting bolt holes. It is also crucial to provide accurate fixture details and their locations in the new drawing. Additionally, a detailed bill of materials enumerating all the necessary materials is required to guarantee a successful project execution. Introducing the remarkable art of shop drawing, also referred to as fabrication or manufacturing drawing. Each assembled piece is given its own distinctive identification tag, known as an erection mark.

These meticulously labeled pieces are then transported to the construction site where they are unloaded, ensuring that their identifying tags remain intact through either punching or painting techniques. This streamlined process ensures efficient organization and precise placement during construction projects.

In order to effectively visualize how the fabricated pieces fit into the overall structure and which members they are connected to, a detailed drawing known as a GA drawing (general arrangement drawing), Marking Plan, or Marking Elevation is prepared. These drawings are now created with the assistance of advanced Modeling software by specialized steel detailing agencies. In the past, skilled draftsmen painstakingly created these drawings manually, but thanks to technological advancements, the process has become much more efficient and accurate.

Structural Steel Detailing is a critical component of any structural steel construction project. It encompasses the entire process, ensuring precise and accurate fabrication and installation. It’s worth noting that this stage plays an integral role in achieving a successful and high-quality end result.

Structural Steel Detailing, as vital as it is, can be an arduous and time-consuming task. However, ensuring accuracy is crucial in this process.

Even the smallest error in these drawings and data files can cause major headaches during site assembly. It not only leads to delays and complications but also results in costly re-fabrication or field modifications of steel members. Paying attention to design accuracy and avoiding detailing errors is crucial to keeping your project on track and within budget.

The need for timely drawings is a constant source of pressure and tension for those responsible. Skilled workmen eagerly await these essential documents, and the urgency only amplifies the stress. It is crucial to produce these drawings promptly to ensure smooth operations on-site and alleviate the burdens placed on everyone involved.